Lacing

Textiles as a structural art

In the past, structural engineering has eschewed large deformations, implicating them as the cause of catastrophic failures. Recently, this paradigm has shifted away from preventing large deformations in rigid structures towards their controlled application in compliant structures, leading to the possibility of programmatic shape change.

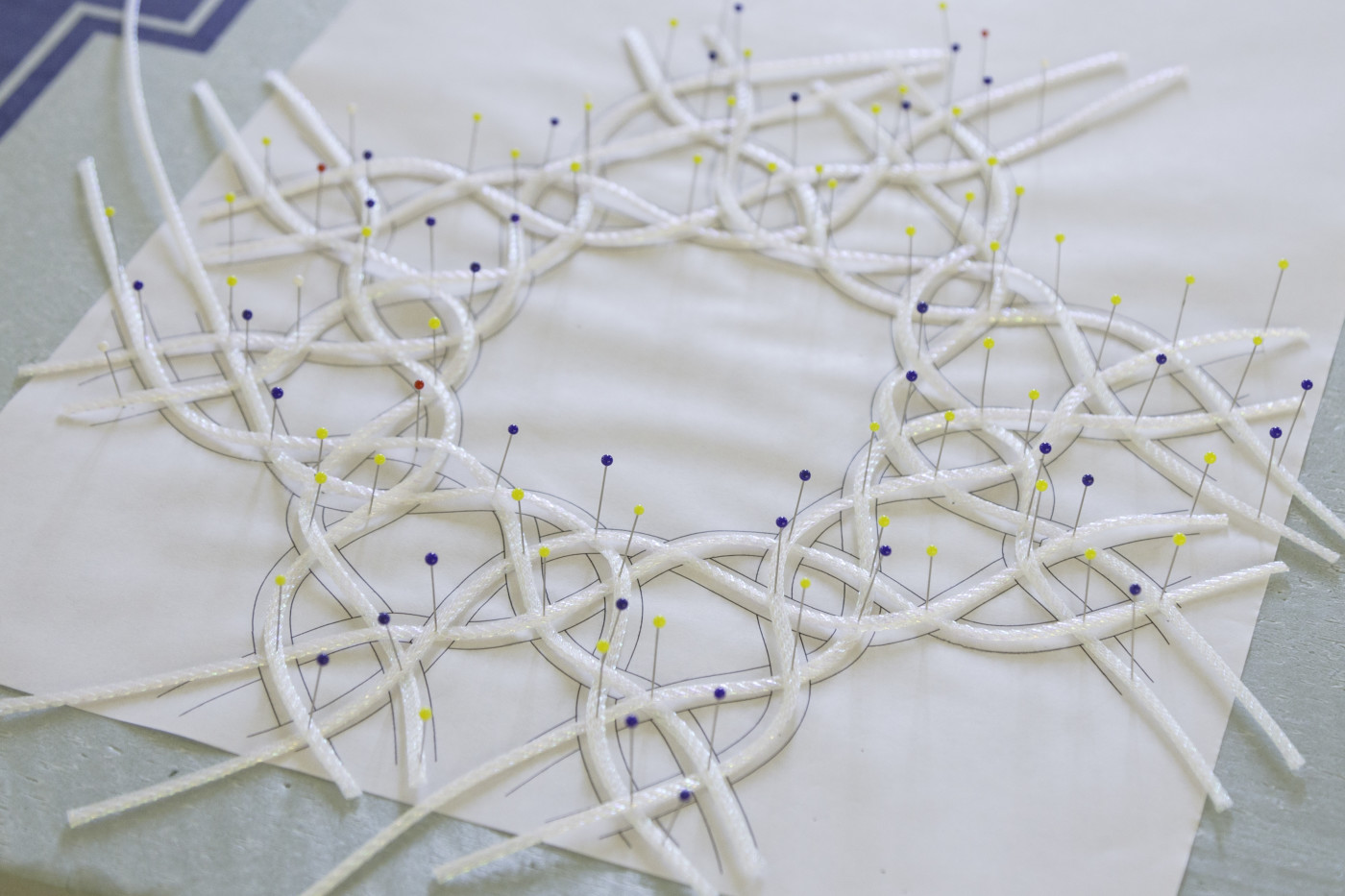

Our interdisciplinary group spanning engineering, mathematics, art, craft, architecture, and robotics is using traditional bobbin lace as a starting point to develop new, largely deformed structural typologies with novel mechanical properties. Bobbin lace is traditionally formed by a braiding technique and is topologically distinct from other textile types such as knitting and weaving. We’ve discovered that when bobbin lace is constructed with a ribbon-like material with non-negligible bending stiffness, the resulting structure will pop out-of-plane as it seeks to minimize bending energy.

We are working with this phenomenon to develop reversible, fabrication-aware structures that could find applications in robotics, medicine, or even be deployable at the architectural scale.

- Date: 2018–present

- With: Sigrid Adriaenssens, Veronika Irvine, Francesco Marmo, Stefano Gabriele, Stefana Parascho

Above: Initial prototype of rose ground bobbin lace showing two concave and two convex nodes. The model pops out-of-plane as it seeks to minimize bending energy.